Founded in 1982, Franco Caruso Marmi e Graniti S.p.A. of Vittoria, Ragusa, has developed into a diverse stoneworking operation, with multiple quarries and stoneworking plants. In fact, Caruso reports that its remarkable growth over the past two decades has made it the largest stone producer in all of Southern Italy.

Franco Caruso explained that the Province of Ragusa has been known for its limestone for over a century, and it developed into a solid stoneworking region. However, during the course of the 20th century, some local companies were losing business to the growing stone industry in Carrara, Italy. As a result, fabricators traveled north to Carrara to re-learn the trade, and ultimately moved back to Ragusa. Consequently, the region now has a multi-stone culture, and Comiso is developing international renown as a block-processing center. Today, Caruso has grown to a company with over 150 employees.

On the quarrying end, Caruso extracts “Petra di Comiso†limestone from its own quarries in Ragusa. Stone is extracted from traditional above-ground sites as well as an underground site.

At the open air quarries, stone is extracted with the help of traditional heavy equipment, including Caterpillar front loaders and backhoes. At one location, the open quarry and the underground quarry are on the same site, along with a sawing station to trim blocks. At the underground section of the quarry, blocks are cut free with a Fantini Model 70 chainsaw, representing the state-of-the-art for this technology.

Caruso's fabrication facilities in Ragusa include two factories, one for limestone production - including hand-made architectural elements and tiles - and another for processing granite and marble blocks into slabs.

At the limestone production shop, blocks are first cut to size with a large disc saw, and then skilled artisans shape and finish them into items such as balustrades, columns, split-face cladding, monuments and other decorative items. The shop also produces limestone tiles in a variety of sizes and finishes.

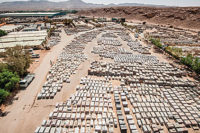

Caruso's facilities for marble and granite production can be compared to any of the leading mass-production stone plants in the world. A large inventory of blocks is maintained at all times, and the company has invested in state-of-the-art machinery from Barsanti.

Blocks are processed on massive Barsanti gangsaws that are 7 meters (23 feet) wide, and can process four blocks at one time.

Following a major global trend, the shop has a complete Barsanti resin line, where slabs are treated with Tenax resin products. The driers on the resin line, which was purchased a year and a half ago, can hold up to 90 slabs at one time, allowing for mass production of cured resin-treated slabs.

Marble and granite are processed in separate buildings, and the slab polishing lines are from Barsanti, including a 14-head unit for marble and a 20-head unit for granite.

Overall, the company produces 800 slabs of granite and 500 slabs of marble per day. It also produces tile in both marble and granite, and totals 4,300 square feet of tile per day.

The company exports much of its production to the U.S., and it also ships to markets within Europe.