Operating fabrication facilities that total more than

100,000 square feet, Top Master of Kansas

City, KS, grew from a

garage shop through expanding, investing and excellent customer service.

For a company founded in the garage of its original owner, it is apparent that Top Master, Inc. of Kansas City, KS, has led a successful path - now operating fabricating facilities that total more than 100,000 square feet. Over the years, the company has continued to thrive through expansion, investments and excellent customer service.

Formed in 1984, Top Master originally provided solid surface countertops to kitchen dealers, builders and remodelers throughout the Kansas City Metro area. “We quickly became known as a company that offered top-quality products and superior customer service, and expanded our services to the commercial industry,” said Manager of the Commercial Division, Mike Varone.

Slabs are processed on two CNC stoneworking centers

from Northwood Machine Manufacturing Co. of Louisville, KY. The machines are

equipped with vaccum pods from Blick Industries of Laguna Beach, CA.

Top Master’s biggest advancement in recent times, however, has been the conversion of its templating and fabrication process from manual to automated. “We’ve become more efficient through automation in our production lines and more sophisticated in our approach,” said Stone Shop Manager Dale Jordan. “In this economy, you have to produce more product for less money.”

Additional equipment includes a Northwood NW-257

high-tech dual-table SawJet, which aids in producing curves and complex work.

Equipment and investments

Top Master’s main facility in Kansas City, KS, is about 60,000 square feet, which primarily houses its solid surface warehouse, corporate office and showroom. Its separate granite shop is 30,000 square feet, and the company has an additional 15,000-square-foot facility in Wichita, KS, which houses an installation facility and showroom.Equipment for Top Master includes a NW-257 high-tech dual-table SawJet from Northwood Machine Manufacturing Co. of Louisville, KY, which aids in producing curves and complex work. The SawJet utilizes a waterjet pump and cutting nozzle from KMT Waterjet Systems of Baxter Springs, KS. For advanced edge processing, two Northwood 158EDS CNC stoneworking centers are in place, which utilize ADI tools from GranQuartz of Tucker, GA, as well as tools from and Tyrolit of Italy. The CNC machines are equipped with vacuum pods from Blick Industries of Laguna Beach, CA.

Slabs are additionally cut by four HTO-1B bridge saws from Marmo Meccanica of Italy, and flat edgework is completed with the help of two LCV 711 flat edge-polishing machines and four LCT 522 vertical polishing machines also from Marmo Meccanica. A Pro-Edge III automated edging machine from Park Industries of St. Cloud, MN, also helps with edgework, and material is maneuvered throughout the shops using vacuum lifters from Anver Corp. of Hudson, MA.

The Northwood SawJet utilizes a waterjet pump and

cutting nozzle from KMT Waterjet Systems of Baxter Springs, KS.

Moreover, the company uses the SlabsmithTM system from Northwood Designs, Inc. of Antwerp, NY. The system was designed as both a manufacturing aid and sales tool. A digital photo of the slab is taken, and the system’s Perfect MatchTM module is for optimized nesting of the various parts. The system allows the user to quickly and easily manipulate the nest for the best results, and users can watch the results in real time as the nest changes. A picture of the finished countertop can be created for customer approval, and a DXF file of the nest can be exported for manufacturing.

Jobs and inventory are managed through JobTracker software from Moraware of Reno, NV, and the company has also recently invested in updating its vehicle and shipping fleet.

Along with the aid of technology, Top Master reports that the dedication of its employees has helped combat the current economic conditions and the challenge of increased competition.

Material is maneuvered throughout the shops using

vacuum lifters from Anver Corp. of Hudson,

MA.

Devotion to great service

Top Master currently employs 170 individuals, many of which take the extra step to ensure what the company calls “overall great service.” “We do everything we can to maintain that status,” said Chief Operating Officer, Dan Richardson. “On the residential side, if customers have problems, we take care of them. For us, we’ve chosen to get a little deeper in partnerships with Lowe’s, Home Depot, etc. We’ve taken a much larger market share of those companies than anybody else. Those are the forefront of [our] remodel work.”“All of our employees are proactive with having face time with customers and developing relationships so they feel comfortable,” added Varone.

Because a large amount of Top Master’s employees have been with the company for more than a decade - rising from entry level - many are able to excel at every facet of fabrication and installation, according to Combest. The company also welcomes new employees to its business, but it has a stringent hiring process.

“We are always excited to hire people that can bring new ideas and innovation to the company,” said Richardson. “But we do not take the decision to hire the right person lightly. The hiring process is pretty intense; we do not make our decision solely on whether the candidate has specific industry experience. We look at each candidate’s worth of integrity, honesty, ability to communicate, and the ability and willingness to learn our trade. In addition, we put our new hires through a lengthy series of post-screening tests that help to ensure the safety of our employees and customers.

“Our training program is more like an apprenticeship,” he continued. “There is some form of class training, but the most valuable training we offer is hands-on job training. Our craftsmanship leaders, also referred to as the artists of the company, take pride in training the new hires.”

Templating is done using the Proliner digital

templating system from Prodim USA of Vero Beach (an example of which is

pictured).

Getting its market share

Top Master’s residential work covers all of Kansas. It additionally has customers in Nebraska, Iowa, Missouri, Oklahoma and Illinois. “We have work that has gone as far as Japan and all over North America for our customers - because they are in different markets as well,” said Varone.The company recently completed work for Children’s Mercy Hospital in Kansas City, MO, Barnes-Jewish Hospital in St. Louis, MO, Scott Air Force Base in Bellville, IL, Mercy West Lakes Hospital in Des Moines, IA, Kansas University Medical Center in Kansas City, MO, the Kansas City Chiefs’ training facility and offices in Kansas City, MO, Garmin World Headquarters in Olathe, KS, and Denver Children’s Hospital in Denver, CO.

Throughout the Continental U.S., work has been completed for such franchises as Applebee’s, McAlister’s Deli, Pizza Hut, Taco Bell, Denny’s, Chuck E. Cheese, McDonald’s, Smash Burger, TCBY, KFC, Fuddruckers, Burger King, Arby’s, Blanc Burger, Taco Johns, Flying J’s, QT, Schlotzky’s, Panchero’s and Carlos O’Kelly’s.

Ongoing projects that Top Master has recently been awarded are the TD Ameritrade Park Omaha in Omaha, NE, which will house the NCAA Division I Men’s College Baseball World Series, the Kansas City Wizards MLS stadium for soccer, Hendrick’s Memorial Hospital in Abilene, TX, and with three phases of the Richard Bolling Federal Building in downtown Kansas City, MO, being completed, Top Master has just been awarded phase four.

According to Varone, Top Master anticipates continuing to provide top-of-the-line products and services to its customers. It is also strives to be an employer of choice and wants to continue growing through expansion into other markets.

Top Master is one of Artisan Group’s founding members. “Being part of the Artisan Group has given us national exposure through their extensive marketing, PR and advertising efforts,” said Mike Kaufmann, President of Top Master, Inc. “Their upper-end products and warranties have afforded us the opportunity to cater an upper-end customer as well as bring variety of product choices across the board.”

Group members average more than 20 years of fabrication experience in the countertop industry. Moreover, all Artisan Group members have achieved - or have begun the process to achieve - full accreditation with the Marble Institute of America. The group is among the first granite fabricators in the world to be working towards this distinction. Artisan Group also provides a complete line of granite care products including: FirstlineTM Sealer, FirstlineTM Clean & Restore and FirstlineTM Shine.

Top Master, Inc.

Kansas City, KS

Type of work: A range of products in stone and solid surface for the commercial and residential community

Machinery and equipment: two 158EDS CNC stoneworking centers and a NW-257 high tech, dual-table SawJet - all from Northwood Machine Manufacturing Co. of Louisville, KY; a waterjet pump and cutting nozzle for the SawJet from KMT Waterjet Systems of Baxter Springs, KS; ADI CNC tooling from GranQuartz of Tucker, GA; CNC tooling from Tyrolit of Italy; CNC vacuum pods from Blick Industries of Laguna Beach, CA; four HTO-1B bridge saws, two LCV 711 flat edge-polishing machines and four LCT 522 vertical polishing machines - all from Marmo Meccanica of Italy; a Park Pro-Edge III automated edging machine from Park Industries of St. Cloud, MN; a vacuum lifter from Anver Corp. of Hudson, MA; a SlabsmithTM nesting system from Northwood Designs, Inc. of Antwerp, NY; Proliner digital templating system from Prodim USA of Vero Beach, FL; JobTracker software from Moraware of Reno, NV; and vehicle and shipping fleet

Number of Employees: 170

Production Rate: Ability to fabricate 1,000 square feet of stone and 1,200 square feet of solid surface a day

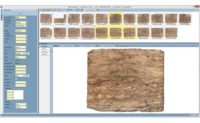

The company uses the SlabsmithTM system from Northwood

Designs, Inc. of Antwerp, NY. The system was designed as both a manufacturing

aid and sales tool. A digital photo of the slab is taken, and the system’s

Perfect MatchTM module is for optimized nesting of the various parts.

The company utilizes Moraware’s JobTracker software to

help manage jobs and inventory (an example of which is pictured).

A range of color selections can be found in Top

Master’s showroom, with displays of engineered stone from companies, including

Silestone, HanStone, CaesarStone quartz surfacing, LG Viateria, Radianz,

Vetrazzo from Polycor and IceStone.

Top Master recently completed front reception and bar

area work for Studio Movie Grill, which features DuPont Zodiaq.