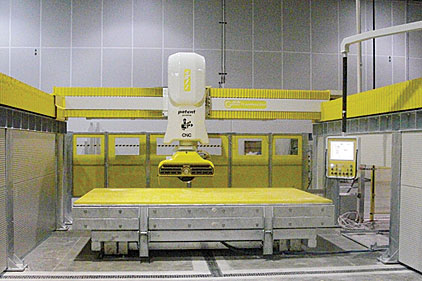

All of GMM’s machines in the CNC range are true five-axis saws. Featuring software designed in house at GMM, the CNC range features the same touch-screen interface, giving the operator a user-friendly and intuitive workstation from where the machine can be controlled totally manually or programmed to run completely automatically.

The Egil (just one in the line of CNC bridge saws GMM offers) is a high-speed, high-precision automated slab processing saw, while still being able to be used in the “traditional” hands-on way of working. The Egil can (upon request) be equipped with a “cassette”-style automated loading/sawing table exchange system, camera/photo station, vacuum system for piece relocation and/or unloading and CAD station for creating DXF files.

The fully automated system replicates what operators have been doing manually for many years, but at another level in terms of speed and accuracy. This includes the design of the DXF files, loading and positioning of the slab, the camera capturing an image of the material and the proprietary intuitive CAM (Cuts from CAD). Each stage flows seamlessly from one to the next, making the whole process fast and efficient.

The on-board touch-screen interface is clear and well laid out, giving the operator the chance to nest pieces according to slab color/pattern variation in a short period of time.

According to GMM, studies have shown that projects cut this way reflect a reduction in operator manpower and an increase in productivity, giving the client a range of cost-saving benefits — not only in the sawing process, but in the secondary profiling/polishing stages. Moreover, incorporating the vacuum system offers a better return on each slab by moving pieces before performing all the cuts. This takes place without any operator intervention, again not only saving time, but also material.

From the entry level CNC Brio to the fully equipped Zeta, GMM offers machines that are suited for all requirements.