The concept of the park dates to the late 1960s, when the drive for urban renewal was becoming prominent across the U.S. Following this trend, New York City Mayor John Lindsay sought to transform Roosevelt Island (referred to as Welfare Island at the time) into a lively residential community.

The New York Times advocated renaming the island in honor of President Franklin D. Roosevelt, along with constructing a memorial to him. An editorial released during this period reads: “It has long seemed to us that an ideal place for a memorial to FDR would be on Welfare Island, which...could be easily renamed in his honor... It would face the sea he loved, the Atlantic he bridged, the Europe he helped to save, the United Nations he inspired.”

In 1973, New York Governor Nelson Rockefeller and Mayor Lindsay announced the project, along with the appointment of Kahn as the architect for the memorial. Thereafter, however, Rockefeller became Vice President of the U.S., Louis Kahn finished his work and died unexpectedly, and the City of New York was facing bankruptcy.

Over time, public interest in Kahn’s work intensified — in part due to two separate occurrences decades after his death. One was a documentary that his son, Nathaniel, produced entitled “My Architect,” and the other was an exhibition of Kahn’s drawings at The Cooper Union in New York, co-curated by Gina Pollara, who is now Executive Director of Four Freedoms Park.

According to Four Freedoms Park’s administration, efforts to build the park received a serious boost in 2005, when William vanden Heuvel, former U.S. Ambassador to the U.N. and the Founder of the Franklin and Eleanor Roosevelt Institute, revived the project. In March 2010, the Alphawood Foundation of Chicago jump-started the funding efforts through a $10 million grant. Since then, Ambassador vanden Heuvel has led the effort that has raised more than $54 million from private and public sources to build the project.

A timeless design

Kahn’s envisioned the park as a celebration of the Four Freedoms, as articulated in President Roosevelt’s famous State of the Union speech on January 6, 1941:

• Freedom of Speech and Expression

- Freedom of Worship

- Freedom from Want

- Freedom from Fear

The park sits on a triangular 4-acre plot of land on the southern tip of Roosevelt Island, and appropriately, it overlooks the United Nations complex on Manhattan’s East Side. President Roosevelt coined the term “United Nations,” and planning for the U.N. began during his administration.

The focal point of the park is a 1,050-pound bronze bust of President Roosevelt, which is an enlargement of a sculpture originally created in 1933 by Jo Davidson, one of the most prominent American sculptors of the 20th century. Davidson had sculpted a life-size clay bust during two working sessions with President Roosevelt at the White House.

Mounted in the sculpture niche, with the Four Freedoms engraved on its south-facing side, the bust stands at the entrance of what Kahn called the “Room,” a 60- x 60-foot open plaza made of granite.

A once-in-a-lifetime stone project

Construction on the park began on March 29, 2010, and it proved to be a unique experience for North Carolina Granite Corp. “We had heard about this project on and off over the years,” explained William Swift, President of North Carolina Granite Corp. “This time, we made a visit to the construction manager and the architect, and we were specified for the project. They visited the quarry and the plant, and they asked for stones for the mock-up.” The construction manager for the project was F.J. Sciame Construction Co., Inc., while Mitchell/Giurgola Architects was the architect-of-record.

To complete the project, North Carolina Granite Corp. quarried 12,100 tons (roughly 24 million pounds) of granite for the project. “That comes out to about 2,900 net cubic meters, and we quarried 4,000 gross cubic meters,” Swift said.

|

Four Freedoms Park New York, NY |

|

Original Architect: Louis I. Kahn, FAIA Administrator: Four Freedoms Park Conservancy, New York, NY Architect of Record: Mitchell/Giurgola Architects, LLP, New York, NY Owner’s Representative: John Conaty, Architect Construction Manager: F.J. Sciame Construction Co., Inc., New York, NY Landscape Architects: Harriet Pattison and Luis Villa/Lois Sherr Associates Geotechnical and Civil Engineer: Langan Engineering, New York, NY Stone Quarrier/Processor: North Carolina Granite Corp., Mount Airy, NC Stone Consultant: Swenson Stone Consultants, Hanover, NH Stone Installer: Port Morris Tile & Stone, Bronx, NY Stone Engraving: The John Stevens Shop, Newport, RI |

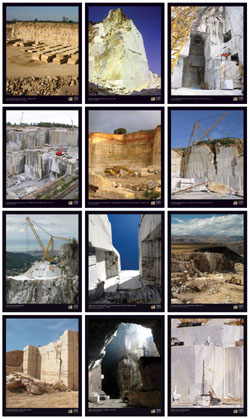

He added that the sheer size of the Mount Airy site made it possible to execute the project. “The Mount Airy quarry is the world’s largest open-face quarry, with 60 open acres,” Swift explained. “We quarried the blocks with wire sawing and drilling, and there were more than 70 stones that were to make 12 x 6 x 6 feet. Since our quarry is so large, we have several areas where we could pull blocks to make these sizes.

North Carolina Granite Corp. completed the overall supply process in three phases. “The quarrying process took us about a year, along with other projects that we were working on,” Swift said, adding that the stone for Four Freedoms Park came from a specific area of the site. “We took them to an area at the east end of the quarry, where they felt the stock was more desirable, and that’s where the material came from.”

Realizing a 40-year-old vision

In terms of stone processing, North Carolina Granite Corp. was tasked with processing stonework that was conceived four decades ago. “Our contact at Mitchell/Giurgola was John Kurtz, and we worked closely with Gina Pollara, Executive Director for the Park,” Swift said. “Gina was the project manager to a certain degree, and she was hands-on throughout the project. Consulting for the owner was Malcolm Swenson and Stephen Castellucci of Swenson Stone Consultants, and the installation team of Port Morris Tile and Marble, led by Anthony Vespa, did a tremendous job.”

North Carolina Granite Corp. processed material of all sizes for the project, including 190 individually crafted stone elements for the “Room.” This is the element of the park that features the 70 largest granite blocks. In a testament to the skill of the company’s stoneworking skill, the stone columns in the “Room” are separated by openings measuring only 1 inch wide — a feat that Swift credits to the experience of North Carolina Granite Corp.’s employees. “It was a lot of work,” he said. “When you’re dealing with massive stones that size, you have to work it by hand. We would use wire saws to get as close as we could [to the size of the finished pieces], and then we would machine them by hand. Most of the guys who worked on this project were quite experienced, from 30 to 35 years each.”

Because the details of stonework were specified in the early 1970s, much of the work had to be cut using the methods and technology of that time. “It was really just wire saws and hand finishing,” Swift said. “If you consider the sizes of the pieces, most CNCs wouldn’t be able to fit it. You don’t see a project like that today, but it was typical for the ‘50s, ‘60s and ‘70s. The smallest pieces on the job were the copings that run along the water, and they were 12 x 3 x 2.5 feet.”

Speaking on challenges, Swift said that careful thought had to be given to how the large pieces would be handled. “I’d say 90% of the pieces were large — 10,000 to 70,000 pounds,” he said. “The columns were finished on four sides, which meant they had to be turned, and you had to make sure you didn’t damage the pieces as you turned them.”

Once the pieces were processed, the next challenge was transporting them to the jobsite. “We had the crane capacity to handle the large stones in the plant, but special trucks provided by Yarborough Trucking permitted us to haul large overweight and oversize product to New York,” Swift said. “Once in New York, most of the pieces for the ‘Room’ were barged over to the island; they exceeded the weight limits of the bridge that takes you to Roosevelt Island.”

In addition to the cut granite, North Carolina Granite Corp. processed over 261,000 cobblestones to be used in the park. These pieces are thermal topped with split edges, and each one was hand-placed by the installer.

Construction details

Construction of the Park took 30 months, and the first phase was construction of the “Room,” which was completed by Port Morris Tile & Stone over a period of 16 months. Overall, FDR Four Freedoms Park is considered to be the heaviest stone-setting job ever to be undertaken in New York City, and Port Morris had 100 trained stone setters on the project.

Additionally, President Roosevelt’s immortal words were hand-carved into the granite walls by Nicholas Benson, a MacArthur Fellow and third-generation stone carver. Benson, owner of The John Stevens Shop in Newport, RI, is known as a master of hand-letter carvings, and his inscriptions and decorative reliefs can be seen throughout the U.S., including Yale University, the National Gallery of Art, the World War II Memorial and the Dr. Martin Luther King Memorial.

The “Room” is supported by both bedrock and caissons, and the “riprap” — the rock barrier that protects the edge of the island from erosion — is made up of 11,000 cubic yards of hand-placed granite gneiss, 65% of which was recycled from the site.

The memorial was officially dedicated on October 17, 2012, and it opened to the public on October 24, 2012. For North Carolina Granite Corp., the completed park serves as an example of the large-scale work that can be done in natural stone. “When you have a project that has that type of mass and scale to it, it has so much more meaning,” Swift said. “If those columns were veneered, they just wouldn’t have the permanence. We are hopeful that it will inspire more projects like this.

“All of the feedback we have received has been positive,” Swift continued. “We have a lot of people calling us and commenting on the project; people are using terms like ‘once in a lifetime,’ but we are hoping to see more work like this. We’re not the largest fabricator, but we are a very capable company, and this project is a very good spokesperson for The North Carolina Granite Corp.”