“Previously, church members had to travel to Edmonton, Alberta, or Cardston, Alberta, to visit a temple,” said Jeremy Woolf, principal in charge of the project for Abbarch Architecture Inc. “The church has a large membership in the Calgary area which was previously under served.”

According to KEPCO+, some of the project’s greatest accomplishments were achieved during the pre-construction phase. The stone installer analyzed each stone detail proposed on the project and presented multiple enhancement options to the design team. The team identified several details that could be altered to enhance aesthetics, while at the same time improving the schedule, performance and budget. The detail studies alone resulted in a net saving of nearly $250,000 in stone material and installation costs.

KEPCO+ also identified redundant framing between the stone substrate system and the primary structure. Both systems were simplified, reducing the amount of materials needed and therefore improving the budget. Adjacent materials, such as insulation, flashings and membranes were also analyzed, allowing the team to resolve potential constructability conflicts prior to reaching the field.

One particular detail study that proved highly successful was the evaluation of the stonework at the water table. The corner element above the water table course is a diagonally bisected stepped cruciform shape with tapered sweeping elements that flare at the bottom. In the original design, five individual stones would be required to create the corner transition from the water table to the building corner. The jointery between these pieces was not desirable to the architect, so the installer proposed an alternate detail utilizing a single, massive, cubic-carved “plinth” corner element.

In addition to the stone detailing, KEPCO+ assisted in building envelope discussions for incorporating and coordinating the weather barrier and insulation into the stone cladding system. “The final design included a steel frame grid system attached over the exterior gypsum sheathing to the metal stud framing,” said Chris Knaphus, project director for KEPCO+. “This grid system had ‘Hat Channels’ that established the face of the insulation that the stainless steel stone attachment clips were connected to.”

At the completion of the design assist work, KEPCO+ was required to bid for the project in a competitive “hard bid” process; the company was awarded the construction and installation phase of the exterior cladding and site work stone scope. KEPCO+ was later requested to bid, and subsequently awarded, the interior stone scope as well.

The three-story ediface features a center spire design, and is clad in granite quarried and fabricated in China. “The design of the building responded to the sites topography, and the prairie element and setting,” said Woolf. “The slightly art deco nature of the massing is a reference to the existing Cardston Alberta temple, which was an important early temple for the church. The decorative wheat motif carries through the stone carving, the art glass and interior details, and references the agricultural heritage of southern Alberta.”

|

Calgary Alberta Temple Calgary, Alberta, Canada |

|

Owner: Church of Jesus Christ of Latter-Day Saints Design Architect: Abbarach Architecture Inc., Vancouver, British Columbia Project Architect:Abbarach Architecture Inc., Vancouver, British Columbia General Contractor: Stuart Olson, James Logan, Calgary, Alberta, Canada Stone Supplier/Fabricator:Bestview International, Glenview, IL (exterior granite); Daltile, New York, NY (interior stone) Stone Installer: Kepco+, Salt Lake City, UT |

Installing the stone

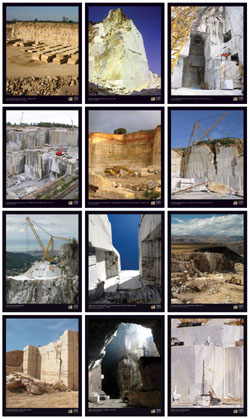

The temple used 30,000 square feet of exterior granite cladding, fabricated from G655 Temple White, which was supplied by Bestview International of Glenview, IL. There were also 6,500 square feet of site work granite and 16,500 square feet of interior stone, which was supplied by Daltile.

For the exterior, the typical cladding piece was 3 feet long x 2 feet, 3 inches tall x 2 inches thick, with cubic-shaped pieces weighing 3,000 pounds. The interior was done with 18- x 18-inch stone pavers, with cubic-shaped pieces weighing 700 pounds.

The typical veneer for the exterior cladding was 3 to 4 cm thick, while the stonework for the cubic water table pieces ranged from 3 to nearly 8 inches thick.

In addition to the exterior, a massive stone baptismal font and 8,000 square feet of stone flooring and staircases were installed inside the temple.

Challenges with installation

Some of the most challenging aspects of the stonework for KEPCO+ included coordinating stonework design changes and incorporating those changes into stone delivery and installation schedules in time to meet project completion dates. “Additionally, because of international labor relations with Canada, all installation labor had to be subcontracted with local installers,” said Knaphus. “This required a significant amount of supervision and coordination by KEPCO+ to ensure things were done correctly, with quality, and on schedule.”

KEPCO+ solicited bids from local installation companies for the labor portions of the work; the company ultimately selected a large masonry firm to install the exterior granite cladding and site work elements and a tile and stone company for the interior stone scope. KEPCO+ also contracted with suppliers and installers for the steel grid framing system, and weather barrier and insulation.

The management of the multiple lower tier subcontractors, who had no previous experience with the high-quality demands of the Latter-Day Saints church for temple work, resulted in a significant investment of time and resources for KEPCO+.

The company had a project manager and a field operations manager, as well as a general superintendent assigned full time to the project.

The project broke ground on May 15, 2010, and in October of 2012, the Calgary Temple was dedicated. Tens of thousands of patrons visit the temple annually, and it has quickly become a significant landmark in Calgary.