Celebrating its 90th anniversary last year, Dakota Granite Company, based in Milbank, SD, has been a longtime stone producer. It opened its doors in 1925 as primarily a quarrier and monument manufacturer. Through the decades it has weathered some storms, but today continues to thrive. Currently, the company operates four quarries in South Dakota, one in Minnesota and is in the process of opening three sites in Wyoming for Red sandstone, Teton Taupe and Casper White.

Dakota Granite Company, which now has 75 workers, was originally founded by partners George Liebenstein, Wesley Swenson and Alexander Dewar, and it is presently owned by a family of stockholders. Since 2010, the company has been under the direction of Rick Dilts, CEO, who began his career at Dakota Granite Company as a territory representative more than 15 years ago.

On August 15, 1930, lightning struck the plant and everything was destroyed but a two-room office building. Insurance covered most of the loss and a new 7,200-square-foot plant was occupied by that November. In 1941, The Pearl Harbor attack plunges the nation into World War II, and the company suffers for lack of steel, rubber, coal and gasoline. Many of Dakota Granite Company’s best men were taken for the war effort.

But despite these setbacks, the company managed to move on. In 1979, it shipped its first container of granite from the port of Duluth, MN, to Italy. As time progressed Dakota Granite Company continued to make investments and built a state-of-the-art operation that put them on the course for success.

Marketing it products

The company opened a tile plant in 1989, which ran until 2003. It then started its commercial division in 2006. “Our main customers for our commercial division consist of contractors, developers and masons,” said Dilts. “It seems like every aspect of the building project contacts us at some point, but for the most part, the installers are the ones we like dealing with.”

According to Dilts, Dakota Granite Company’s monumental division is by far its largest area of sales at 83%. The company’s block division comprises 8.5% of sales, while the commercial division is 8%.

“We do have a national distributor for our pavers,” explained Dilts. “The rest of our products are sold directly to the installers and developers. Most of our projects are shipped directly to the jobsite for installation.”

Among the granite varieties available through Dakota Granite Company’s commercial division are Dakota Mahogany Sunset, Dakota Mahogany Whetstone, Dakota Mahogany Brown Velvet, American Bouquet and Bellingham. The company fabricates pavers, cobbles, fountains, curbing, steps and treads, wall panels, tiles, slabs, panels, cubic work, architectural elements, cut-to-size pieces and columns for applications nationwide. Recently completed projects include the expansion of Arlington National Cemetery and a PNC Bank in Pittsburgh, PA.

The quarries

Between all of its quarrying sites, Dakota Granite Company has 17 employees. “We’re currently operating five locally and are opening three in Wyoming,” said Dilts. “Seven are granite and one is red sandstone. Three of the five local quarries would be considered Dakota Mahogany. American Bouquet and Bellingham are limited production quarries, which we only go into when we need to. We’re currently quarrying in the Teton Taupe quarry west of Casper, WY, and do have blocks on the ground available for sale. We have been in the second Wyoming quarry since September. It is a red sandstone that has been marketed in the past for institutional buildings west of the Mississippi. Both of these quarries were already in the infancy stages when we took them over. The third is Casper White, which also comes from the Casper, WY, region. It is a brand new quarry that we will open up in October with blocks ready to ship hopefully by the end of the year.”

Dilts explained the company is currently operating a mix of Benetti and Sky Stone wire saws in its quarries. “The last couple of years, we have begun cutting up the tipped benches with wire saws rather than drilling out the blocks,” he said. “This gives us more uniform blocks and saves wear and tear on our drills, which are much more expensive to replace or repair than wire saws. We operate a variety of drills, but mostly Perfora drills and a Park Industries Raptor drill is on order.”

On an annual basis, the company produces roughly 4,500 cubic meters of stone from its quarries. “We use a majority for our own production,” said Dilts. “North American fabricators and China consume most of the rest. The overseas buyers use it either for processing and shipping back to the U.S. or for projects in their own country.”

The fabrication process

Dakota Granite Company runs a 110,000-square-foot fabrication facility with 38 workers. It is equipped with a diverse lineup of machinery, including 11 Hensel Burkhardt pieces of equipment and six machines from Park Industries, as well as various other types of equipment. In 2016, the company invested in a new Donatoni saw for slants and hickeys and a Breton SmartCut 550 Optima saw.

“We start out looking at what we want to accomplish with the machine,” said Dilts, when explaining how they decide on what equipment to purchase. “This usually eliminates a few companies off the list. Then we look at how well their service department will handle issues. This usually involves talking to other companies who have their equipment if it’s not a company we’re already dealing with. This always eliminates a few more. Then we look at price.”

The Donatoni saw has a 64-inch blade which can saw up to 24 inches vertically or bevel slants up to 18 inches tall. “It is also CNC controlled, which means more consistency in movement resulting in a better product for our customers,” explained Dilts.

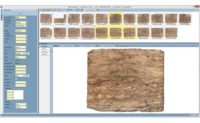

The Breton SmartCut 550 Optima saw was purchased primarily for Dakota Granite Company’s columbarium and building stone production lines. “It is a state-of-the-art complete sawing system that places an emphasis on efficiency and slab yield,” said Dilts. The saw comes with two cameras that can be used to take pictures of the slabs either when they are done being polished or loaded on to the saw conveyor. The operator can then look at the picture and import the pre-drawn work pieces to layout on the slab. This allows us to maximize slab yield by working around any imperfections. The saw is also 5 axis and CNC controlled, and can also be used to core holes and saw inside corners for relief cuts.