Having outgrown their family style home in Clark, WY, the Monks of the Most Blessed Virgin Mary of Mount Carmel were seeking a new place of solitude. With the majestic mountainscape of the Rocky Mountains nearby, it was the obvious choice for their relocation. Through the efforts of the New Mount Carmel Foundation and the generosity of a few benefactors, the monks were able to acquire mountain property in Meeteetse, WY, for their monastery in the fall of 2010. Seeking simple durable materials that will withstand the test of time, the monks chose natural stone for their spiritual retreat. Faced with cost provisions, the monks took on the impressive challenge of learning to operate a CNC stoneworking center and fabricate all of the stone needed for the project themselves.

“We wanted to build a monastery that would last for many generations of monks,” explained Brother Gabriel Marie. “Stone was the obvious choice since all of the monasteries and churches of Europe are built of stone and have been standing for a thousand years. Natural stone also has a beauty that lasts for centuries, unlike many other forms of architecture.”

When the decision was made to build a new monastery, the monks embraced it whole-heartedly. Natural stone was the perfect complement to the Gothic-style of architecture that was chosen for the monastery.

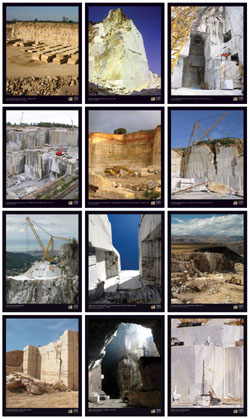

“We wanted to use a stone that was nearby, and researched and visited many quarries in the surrounding states to find the right stone that would be both lasting and beautiful,” said Brother Gabriel Marie, adding that after their extensive search a final decision was made to use Kansas Silverdale limestone for all of the cut stone and Colorado Buff sandstone for the field stone. “We were mainly interested in the longevity and structural capabilities of the stone, as well as its natural beauty. We also wanted to make sure we could get large enough stone for the pieces we would carve. We have been working with Pray Stone for the Kansas Silverdale limestone and Arkins Park for the Colorado Buff sandstone. Both have fulfilled our needs admirably.

“After we realized the astronomical cost of paying a company to carve and install the stone on our monastery, we knew that was not an option,” Brother Gabriel Marie went on to say. “As monks, we are not wealthy. We are supported by our own coffee roasting industry, Mystic Monk Coffee (www.mysticmonkcoffee.com), and the donations of generous people who believe in our way of life. We could not in good conscience spend the money given to us in paying someone else to build a monastery. The carving and installation of the stone was the most costly line item, so we decided to tackle that ourselves.”

Researching machine manufacturers

No one in the monks’ community had any previous experience with stone fabrication or working a CNC machine. “However, we knew we had to learn since we could not afford to pay someone else,” explained Brother Gabriel Marie. “So we dove in and began researching how to carve stone in today’s world. CNC machines were a logical conclusion.”

In 2013, the monks conducted a very thorough research on the various manufacturers of CNC machinery. “We were trying to find the one that was best for us, and also fit in our budget,” said Brother Gabriel Marie. “Two of our monks visited several different stone fabrication shops to see the machines of different manufacturers in action. After this, we narrowed our options down to three [manufacturers]. All three made excellent machines that were capable of fulfilling our needs. Prussiani’s machines did stand out for their strong and beefy construction. The different parts of the machine, especially the bridge, were significantly thicker. In the end, Mario Prussiani gave us such an incredible offer on a New Champion Plus 1300 that we decided to purchase his machine. We have not been disappointed by that decision. Prussiani has been stellar over the years, helping us with any questions we might have, and there were a lot in the first year. We do owe a large portion of our success in learning how to use CNCs to Prussiani’s tech support.”

Brother Gabriel Marie explained that the monks chose the Champion Plus 1300 because it was large enough to handle all of the different pieces they needed to carve for their monastery. “In early 2016, we obtained two Champion Plus 700s to aid in carving the stone,” he said. “At the time, we were looking into used machines, since again, our budget was tight. However, Mario offered us an unbeatable price on two new machines with full three-year warranties. These extra machines have been indispensable in continuing the fabrication of stone for our monastery.”

Benefits from CNC technology

The majority of the pieces carved for the new monastery are very ornate and complex. “There are only two real options for them — carving by hand or using CNC machines,” said Brother Gabriel Marie. “CNC machines are significantly faster than hand carving. They also allow us to carve incredible three-dimensional pieces. Since all of the design is done in a computer in advance, you can tweak and change the design over and over again until it is perfect — before you ever place the piece on the CNC. We also use Pegasus CAM, an excellent program that allows us to fully exploit the capabilities of our CNCs. It has an excellent simulation which we use to calibrate the exact amount of detail we put into each piece. Prussiani was indispensable in integrating their machines with Pegasus. It is also notable to mention that we do almost no hand finishing. By leveraging the full capabilities of the CNC, we are able to produce completely finished, complex, foliated pieces without any hand finishing.”

Although the monks purchased the Champion Plus 1300 in 2013, they did not begin their project until the following year. “After a lot of learning, we started carving stone for our monastery in the summer of 2014,” said Brother Gabriel Marie. “We are still working on the monastery today, and hope to be completed within the next few years.

“Prussiani was very helpful in teaching us how to use their machines, but all of the work of cutting and installing the stone was done by the monks,” Brother Gabriel Marie went on to say. “We simply could not afford to pay someone else for this level of craftsmanship. So we learned how.”

Currently, 17 monks are working on the construction of the monastery. “We cover a wide variety of roles — from stonemason to CAM programmer, CNC operator to 3D modeling designer,” explained Brother Gabriel Marie. “We also do all of our own excavation and heavy equipment operation, and roast coffee to help support ourselves. Actually the proceeds of our coffee business cover all the costs of the stonework on the monastery.”

The learning curve

Starting with no previous knowledge, there was a significant learning curve, according to Brother Gabriel Marie. “Since the monks do every single part of the process, from design to installation, there was a lot that we had to learn,” he said. “We started off knowing that a CNC could do everything we needed it to; we just had to figure out how to talk to it. We are still learning today, but I think we have come a very long way. We’ve definitely had our fair share of pieces that didn’t make it. Ones where you would walk away scratching your head, ‘How did that happen?’ But all of it has helped us to understand a little better how everything works. Everything from computer modeling to toolpath programming to handling such large pieces of stone has been tweaked and refined over and over again. We are very happy with the pieces we can produce now.

“Even though the monastery is not finished, it is mind blowing to think about what has happened over the past few years,” Brother Gabriel Marie went on to say. “We can only thank God who has been so good to us, giving each monk the necessary abilities to make this endeavor successful. It is very rewarding to see it all come together in beautiful structures built to last centuries.”

The proposed monastery for the Carmelite Monks will be constructed of simple, durable materials that will last for generations. Indicative of the monks’ traditional manner of living and their monastic roots in the middle ages, the monastery will be designed in a classical, gothic style.