Home » stone cutting

Articles Tagged with ''stone cutting''

Web Exclusive

If planning to purchase a multifunction CNC machine for your shop, here are some facts you need to know

Read More

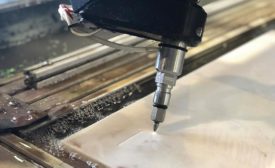

Cutting ultra-compact and porcelain materials

Nick Wadenstorer of BACA Systems discusses the best practices for fabricators when cutting various alternative stone surfaces

February 3, 2020

A Nepalese Gristmill, a Waterjet and Fort Lewis College

Physics and engineering students learned the capabilities of an abrasive waterjet when cutting a gristmill out of granite for the town of Chyamtang in Nepal

November 14, 2019

Enhancements in CNC tooling and accessories

More options are available than ever before when it comes to CNC tooling and accessories – allowing fabricators to become more efficient in cutting natural stone and alternative surfaces.

September 6, 2019

Teaching the art of stone carving

While some came to further hone their skills, others were holding a hand tool for the first time during the Indiana Limestone Symposium which is held annually in Ellettsville, IN

September 6, 2019

Our eNewsletters are a rock solid source of industry insights!

Stay in the know on the international stone and tile industry trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing