Home » waterjet technology

Articles Tagged with ''waterjet technology''

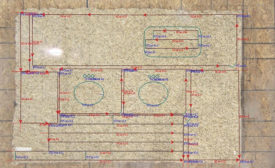

CNC Vs. Sawjet: Which is Best for Your Shop?

When deciding on machinery to add to your shop, consider the capabilities of both a CNC saw and CNC sawjet before making a final decision

May 31, 2022

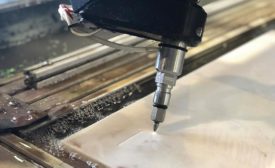

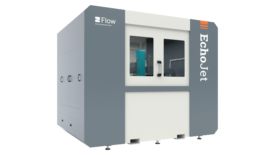

What to know about waterjet technology

Brian Scherick of Flow International Corporation shares with Stone World the benefits of waterjets in the fabrication process, as well as the preferred applications to use them

October 29, 2020

A Nepalese Gristmill, a Waterjet and Fort Lewis College

Physics and engineering students learned the capabilities of an abrasive waterjet when cutting a gristmill out of granite for the town of Chyamtang in Nepal

November 14, 2019

Web Exclusive

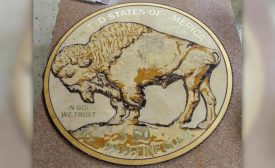

Buffalo Medallion Cut in Stone

A three-dimensional buffalo floor medallion was produced by Creative Edge Master Shop with advanced waterjet technology – demonstrating quality precision and craftsmanship in stone fabrication

March 14, 2018

Fabricator Roundtable: What to Know about Saw/Waterjet Technology

Stone World magazine talked with several fabricators to find out why they invested in saw/waterjet technology and what benefits they are reaping from having the machinery

January 15, 2018

SawJet Technology and the Modern Fabricator

Several facts and benefits to know about using SawJet technology in the fabrication process

January 15, 2018

Our eNewsletters are a rock solid source of industry insights!

Stay in the know on the international stone and tile industry trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1657041008&width=275)